How many of the things that you own do you maintain? Why should you maintain those things? What’s the point? Let me set the scene. You wake up, grab a shower, coffee, breakfast, and you’re out the door. You get into your vehicle and make your way to work but, you notice something’s not right with your car as you slow to a stop. You hear this loud, long squeak. Now, some of you may know that this is your brakes right off the bat and some of you may not know. Either way, you say “I’ll get it fixed later.” A month goes by, still not fixed and now when slow your car to a stop it sounds like Freddy Krueger dragging his knife glove across the pavement. Scary, right? What once would’ve costed you $90 - $180 for the brake pads you needed now, will cost you double or even triple that amount for the brake pads plus the brake rotors you need.

Recent Posts

The use of metal powders is a technique that dates back to prehistoric times. Excavations from the ancient Inca and Egyptian sites have uncovered ornaments and implements produced by this process.

What do you think of when I say the word, Change? No, I’m not talking about what the clerk hands you after purchasing your morning coffee. I’m talking about the act or instance of making or becoming different. How many of you fear it? How many of you embrace it? “That’s the way we’ve always done it” I’ve heard that all too often. John F. Kennedy said “Change is the law of life. And those who look only to the past or present are certain to miss the future”. I know what you're thinking, easier said than done, right? Changing before your competition, thinking forward, and trying new things puts you ahead of the curve. Converting your production line components to Powdered Metal (PM) could be a big advantage for your business. Without Change, we cannot improve.

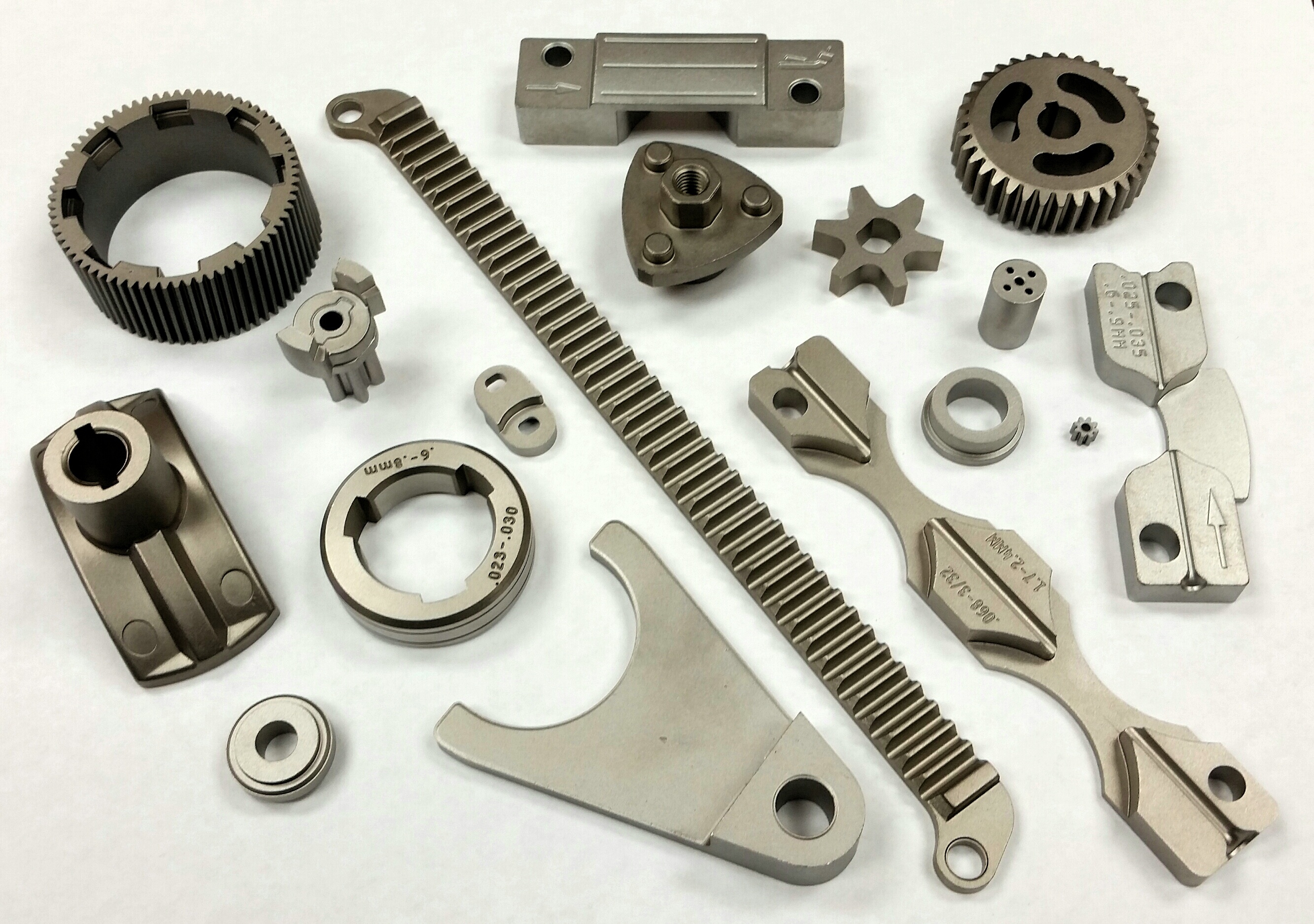

What Are The Right Powdered Metal Parts For Me?

The powdered metal trade is a very popular and demanding industry. The amount of powdered metal parts throughout the world today is enormous! However, there are some companies out there that might not be convinced that powdered metal is the right choice for them. I would like to address one of the questions that prospects have asked us on more than one occasion. “What’s the right material for me?” In order to answer that question, we need to know two things. What material are you currently using (ex. cast, wrought, molded, etc.) and what is the part’s current application and physical requirements (how it is used and what is it used for)?